Relubrication of Slew Drive

While rotating the Slew Drive, inject grease into all the cleaned grease nipples consecutively until a bead of fresh grease forms at least on one seal or at the bearing gap.

Ensure that old grease can flow out of the drive freely.

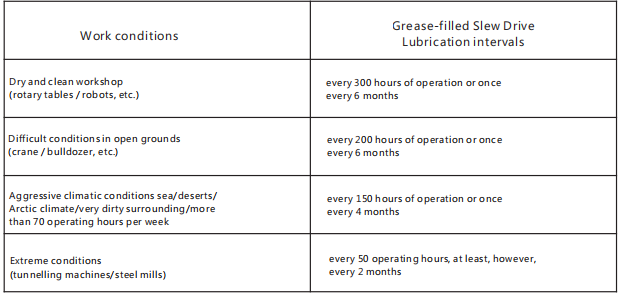

Relubrication intervals depend mainly on the prevailing work and environmental conditions as well as on the version of the Slew Drive.

Exact relubrication intervals can only be determined by tests under actual operating conditions.

Intermediate transmissions are filled with oil; prescribed maintenance intervals are found in the maintenance instruction of the respective manufacturer.

Slew Drives shall generally be relubricated :

*After every cleaning. *Before and after long inactive periods, e.g. for cranes and construction machines during winter months.

*Cleaning a Slew Drive with steam jet or high-pressure cleaner is not permissible!

The table can never replace values established through experience; the most frequent cause of failure of Slew Drives is insufficient lubrication.

The specified values are valid for the following conditions:

*Operating temperature on Slew Drive < 158° F

*Circumferential velocity < 1.64 ft c for SP Slew Drives

c for SP Slew Drives

*Driver rotational speed < 5 rpm for WD Slew Drives

*Low to medium loads

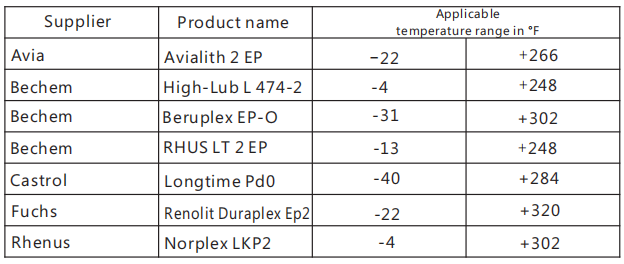

Lubricants: