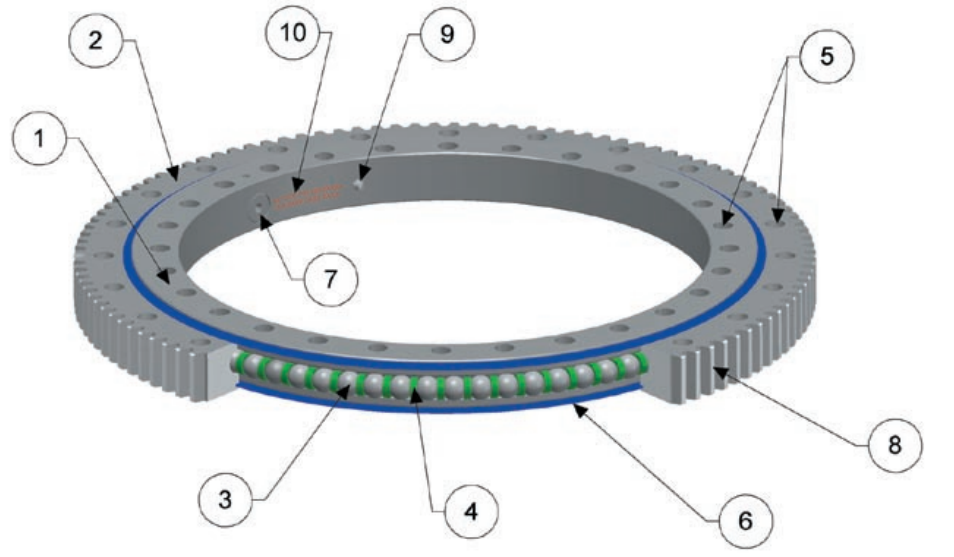

SoCare Slewing ring bearing features

Inner and outer rings (1 and 2)

The bearing consists of an inner and outer ring made of medium carbon steel. Each includes at least one precision raceway arranged to transfer loads and relative motion from one structure of the equipment to the other. The raceways are selectively hardened to the required surface and depth necessary to transmit high stresses imposed during operation of the equipment.

Figure 2-5 reflects the typical hardness patterns of four-point ball (RK, HS, HT, MT, KH, and XT Series) and cross roller (XR Series) bearings. Multiple row bearings (DT and TR Series) receive similar treatment in their highly stressed raceways.

In one location around the raceway, there is an unhardened area referred to as the hardness gap or “soft spot.” This area is relieved to minimize the ability of the rolling element to apply stress on it.

Only one side of each ring is manufactured to be mated with the supporting structure. One or both rings may include an integral drive mechanism such as gear or sprocket teeth to enable the mechanical advantage necessary to overcome rotational resistance and provide relative motion through the bearing.

Rolling elements (3)

Precision rolling elements enable relative rotation and transmit load between the inner and outer rings. Hardened chrome alloy steel balls or rollers may serve as the rolling elements. They are sized appropriately for the anticipated stresses and closely matched to provide uniform load distribution between the rings and minimize rotational resistance.

Spacers (4)

Spacers separate the rolling elements and are designed to minimize friction, skidding, and jamming during rotation. These conditions occur as a result of load distribution and distortion of the mounting structures and bearing rings during operation of the equipment. Spacers are generally made of a plastic material compatible with typical lubricants and operating environments. Occasionally for ball bearings, a ball of smaller size is placed between the larger load-carrying balls instead of a spacer. These are referred to as “spacer balls” and can provide a solution to a unique condition specific to a particular application. Where the application warrants, a separator is used in place of the spacers or spacer balls.

Mounting holes (5)

The ideal hole pattern for attaching both rings of the slewing ring bearing is a full circle of uniformly spaced through holes. It is recognized, however, that the equipment designer cannot always accommodate this type of arrangement and may require tapped holes and even special bolt patterns in one or both rings for assembly and maintenance reasons.

Seals (6)

A seal is included on each side of SoCare slewing ring bearings for retention of lubricant and protection of the bearing from dust and small particle contamination. The seals are made of an elastomer material compatible with most general purpose lubricants having mineral oil and greases using lithium or calcium thickeners. If conditions require different sealing, SoCare

slewing ring bearings for retention of lubricant and protection of the bearing from dust and small particle contamination. The seals are made of an elastomer material compatible with most general purpose lubricants having mineral oil and greases using lithium or calcium thickeners. If conditions require different sealing, SoCare can provide details of additional options upon request.

can provide details of additional options upon request.

Loading (Filler) Plug (7)

The rolling elements in SoCare bearings may be inserted through a hole drilled radially through the non-geared race and then plugged. The plug is retained mechanically with a pin to assure proper orientation is maintained. TR Series bearings, however, do not have a loading plug as they require one of the rings be split for assembly of all the rolling elements.

bearings may be inserted through a hole drilled radially through the non-geared race and then plugged. The plug is retained mechanically with a pin to assure proper orientation is maintained. TR Series bearings, however, do not have a loading plug as they require one of the rings be split for assembly of all the rolling elements.

Gear (8)

Slewing ring bearings can be supplied with gear teeth as an integral part of either the inner or outer ring. They are typically a standard full depth or stub involute spur gear having a 20° pressure angle with provision for backlash and conforming to AGMA Q6 quality. However, where required, modifications of the basic tooth forms, pressure angles, and quality can be provided. For assembly purposes, the maximum point of gear runout is identified with yellow paint. Alternative methods may be applied upon request.

Grease Fitting (9)

At least one grease fitting is supplied in one of the bearing rings for periodic lubrication of the raceway and internal components. On designs with integral gear teeth, it is located in the non-geared ring. The number supplied typically increases with bearing diameter. More or less may be included upon request.

Identification (10)

Identification consists of the bearing part number and serial number. This information is located next to the filler plug.