1.The factors of affecting the machining quality of carbide threading tools for oil pipes and tool machinability.

(a) External factors of the tools ,including:

①、Rationality of the design of the tool structure;

②、Blade face, the profile accuracy, degree of finish and the condition of surface structure;

③、Enforcing quality of cutting edge

④、 Manufacturing accuracy of the rod and the quality of the accessories ,such as break chips.

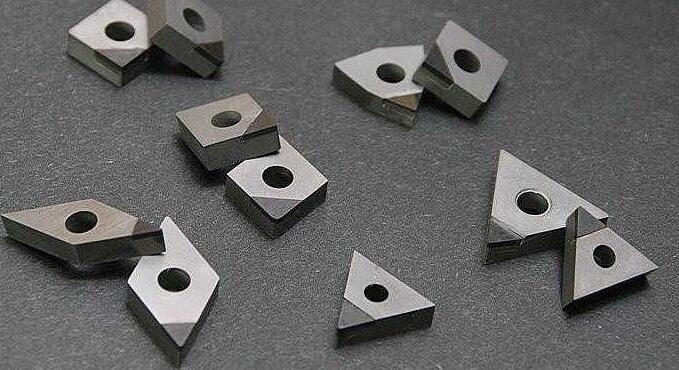

(b) Internal factors of the inserts ,including:

①、Quality and performance of the base material of inserts

②、Quality and performance of the top coating of inserts

③、Materials , performance of the heat treatment of tool rods

(c) Use factors of tools, including:

①、Correct choice and use of tools

②、The statue of thread processing equipment

③、 Mode and effect of cutting cooling

④、 Workability and homogeneity of the machined materials

⑤、 Correct choice for cutting specification of thread processing

(a) (b) depended on tools manufacturer, (c) depended on tools user. Reasonably using tools is very important.

2.Two processing mode of carbide threading tools for oil pipes

Mode of threading(used to process thread oil pipes, casing pipes and boring rod)

The features of the cutting movement.

● Rotational movement of the work pieces (pipes or connectors).The principle cutting movement is occurred.

● Movements and intermittent bites while the tools(threading and roughing tools)move along the generatrix of taper thread.

● Threading is used an the most widely way of processing the thread of oil pipes. According to the production conditions and threading machine, there are two ways: single insert threading and packaged inserts (two blades in general ) threading with tools units. All the drill rod connectors are threaded by single insert threading.

Mode of processing threading head (only used to process thread oil pipes, casing pipes)

The features of the cutting movement:

● Work pieces(pipes or connectors) are positioned and clamped firmly.

● And still movements and intermittent bites while the tools(threading and roughing tools) rotate around the work pieces axis and move along the generatrix of taper thread.

● The ways for processing are internal cropping and external cropping. They are fit for producing oil pipes, tubing and processing connectors efficiently in large number. External cropping contains packaged threading inserts(three blades in general) and roughing tools units; internal cropping contains single insert threading insert and packaged blades in roughing tools units.

At SoCare® , we take pride in our dedicated technical experience with Slew Ring, Slew Drive, even Ball Screw. It's our job to work closely with our customers on a variety of new projects not only as suppliers, but as developers and designers. This involves getting to know you and your project needs inside and out, so that we can dedicate ourselves to creating the ideal solution for you.

Do you have an idea or project in mind that SoCare® can bring to fruition? If so, we want to be your partner. Please contact a member of our team to find out more information.